- Familiarization

The degasser is one of the main solid-state control devices in the process of oil drilling. Its main function is to, to separate the associated oil gas from the wellhead back into the mud, And the gas invaded the dirt. The efficiency and efficiency of deaerator separation are the main metrics for measuring equipment performance.

ZLCQ Centrifugal Degasser / 240 has the characteristics of large processing capacity, High separation efficiency and wide range of applications.

ZLCQ Centrifugal Degasser / 240 consists mainly of explosion-proof motor, electrical control unit, vacuum pump assembly, reducer and separator assembly for gas and gas separation. The design of the structure is reasonable, compact and superior in performance. The gas separator is equipped with a liquid gas separation blade to improve separation efficiency, A new type of suspension discharge device has been adopted, which greatly improves the performance of the whole machine.

- Principle of operation

When using the ZLCQ centrifugal degasser / 240 The liquid-gas separation cylinder is immersed in the drilling fluid. When the motor rotates the spindle, to rotate it, The mud immersed in water is first directed to the separation chamber above the damper at the bottom of the degasser, and the separating blade in the separating chamber rotates, to rotate the drilling fluid to rotate. A thin layer of liquid forms on the inner wall of the separation cylinder, having a thickness of about 2-3 cm in vortex state for spiral upward movement. A rotating layer of fluid forms a centrifugal force field, and therefore the gas phase splits rapidly. The bubble moves in the direction of the axis, and the liquid rests on the inner wall of the separating cylinder. When the bubble reaches the inner surface of a thin layer of swirling liquid, because negative pressure occurs in the separator chamber of the deaerator, The bubble can quickly break through the surface tension of the liquid and rupture, and is quickly removed by the vacuum pump. The degassed drilling mud is spirally lifted along the inner wall of the separating cylinder and discharged from the fluid outlet.

- 1.2 Performance

ZLCQ Centrifugal Degasser / 240 Has a reasonable structure design, stable operation, Low noise level, Long uptime and reliable operation. It is suitable for gas-liquid separation of drilling fluids with various parameters. Mud viscosity range, to be processed, Is 20 °mum. 80-In the 1990s,.

- 1.3 Structural features

- Using a Vacuum Pump, High exhaust efficiency.

· Using Unique Reducer Design, Smooth and constant speed.

· A long liquid gas separation separator is used to increase the separation stroke, And the gas-liquid separation efficiency is high.

· The use of a new type of suspension device greatly improves the performance of drilling fluid. - Design

Design

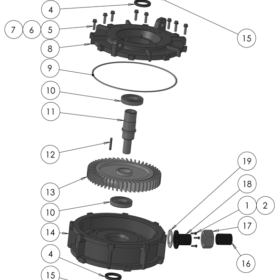

- Dismantling the degasser

Dismantling the degasser

| Number | Name | Stake.

|

Number | Name | Stake.

|

|

| 1 | 18,5 kw explosion proof motor | 1 | 36 | Retaining washer | 14 | |

| 2 | bond | 1 | 37 | Flat Washer | 14 | |

| 3 | Vacuum Pump Assembly | 1 | 38 | nut | 14 | |

| 4 | O-ring | 1 | 39 | nut | 3 | |

| 5 | Gearbox assembly | 1 | 40 | Net seat | 1 | |

| 6 | Bearing Cap II | 1 | 41 | Bearing | 6 | |

| 7 | O-ring | 1 | 42 | stencil | 1 | |

| 8 | Paper | 1 | 43 | Flat Screen | 1 | |

| 9 | Bearing | 1 | 44 | Network Ring | 1 | |

| 100 | Electrical Control Mounting Box | 1 | 45 | Cotter pin pin | 1 | |

| 11 | Stop Ring | 1 | 46 | Spanner | 1 | |

| 12 | 18,5 kw explosion-proof electric control box | 1 | 47 | Inhalation plate | 1 | |

| 13 | Bearing | 2 | 48 | ring | 1 | |

| 14 | bolt | 4 | 49 | Restorative seats | 1 | |

| 15 | Retaining washer | 21 | 50 | Wear-resistant bushing | 1 | |

| 16 | Flat Washer | 15 | 51 | Place for inhalation | 1 | |

| 17 | nut | 8 | 52 | Glands | 1 | |

| 18 | DN25 Low Temperature Flexible Hose | 1 | 53 | bond | 1 | |

| 19 | Internal spline shaft | 1 | 54 | Lower impeller | 1 | |

| 20 | bolt | 14 | 55 | |||

| 21 | Slurry Casing | 1 | 56 | Separation Cylinder | 1 | |

| 22 | Cork | 1 | 57 | bolt | 4 | |

| 23 | stuffing | 1 | 58 | bond | 1 | |

| 24 | Cup | 1 | 59 | bolt | 6 | |

| 25 | Bearing | 1 | 60 | Hex Screw | 6 | |

| 26 | Gland | 1 | 61 | bolt | 16 | |

| 27 | Threaded Connection Plate | 1 | 62 | Retaining washer | 16 | |

| 28 | Retention sleeve | 1 | 63 | Flat Washer | 16 | |

| 29 | Brackets | 1 | 64 | nut | 16 | |

| 30 | skid | 1 | 65 | bolt | 3 | |

| 31 | Hex Screw | 6 | 66 | bolt | 8 | |

| 32 | Retaining washer | 33 | 67 | Seal II | 1 | |

| 33 | Flat Washer | 33 | 68 | flange | 1 | |

| 34 | bolt | 17 | ||||

| 35 | Long Bolt | 6 |

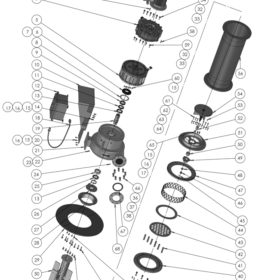

- Vacuum Pump

Vacuum Pump

1.5 Disassembling the vacuum pump

| Number | Name | Stake. |

| 1 | bolt | 15 |

| 2 | Retaining washer | 15 |

| 3 | Bearing Cover | 2 |

| 4 | Gland | 2 |

| 5 | bolt | 8 |

| 6 | Retaining washer | 8 |

| 7 | Flat Washer | 8 |

| 8 | Vacuum Pump Cover | 1 |

| 9 | O-ring | 1 |

| 10 | Bearing | 2 |

| 11 | Vacuum Pump | 1 |

| 12 | bond | 1 |

| 13 | Impeller of Vacuum Pump | 1 |

| 14 | Vacuum Pump Housing | 1 |

| 15 | Paper Overlay φ120 × φ160 | 2 |

| 16 | Short section | 1 |

| 17 | Conical union | 1 |

| 18 | Exhaust seat | 1 |

| 19 | Pad φ50 × φ100 | 1 |

- Advantages of the equipment

1 Impeller Seat Mounting Design Adopts Current PQT Heavy Duty Abrasive Material, which shows, that the service life of a fixed seat on 40-50% above, than a conventional fixed seat, and has a self-lubricating function, which reduces the frequency of equipment replacement.

2 Small footprint, Integrated design for degassing and sludge removal

3 Large amount of processing using long liquid gas separators for suspension;

4 Low Horsepower Engine, Less energy consumption.

- Technical Parameters

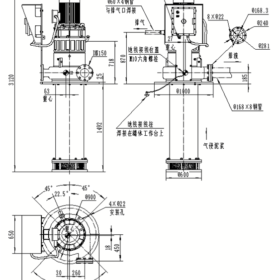

| Series | ZLCQ/240 |

| Processing power (m3/h) | 240 |

| Degassing volume (L/S) | 5 |

| Degassing per cent (%) | ≥85% |

| Motor power (Kw) | 18.5 |

| Motor Speed (RPM) | 1450 |

| Discharge line | Φ168*8 |

| Submersible Length(m) | 1.5 |

| Dimensions(mm) | 1282*1000*3120 |

| Weight(Kg) | 1418 |

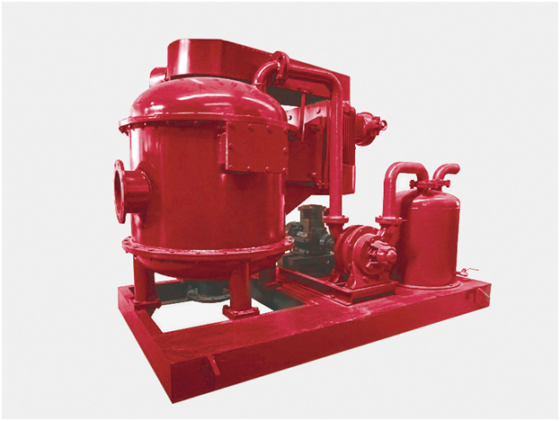

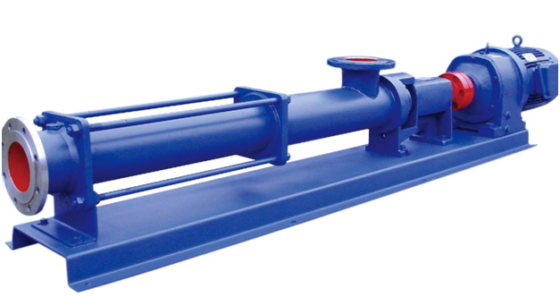

- Equipment Photos

Centrifugal degasser

Centrifugal degasser

Компания Hebei MinYou Petroleum Machinery Manufacturing Co, Ltd

Компания Hebei MinYou Petroleum Machinery Manufacturing Co, Ltd